Certified Service Training for Our Chinese Service Partner

Recently, we had the pleasure of welcoming a special guest at ZES ZIMMER, with whom we have been in close exchange and cooperation for several years. We are referring to Neil Xu, Service Technician of our long-standing Chinese distribution partner GMC-Instruments (Tianjin) Co., Ltd., specifically from the Shanghai branch GMC-I (Shanghai) Power Measurement.

In close collaboration with our technical sales and manufacturing teams, Neil Xu provides local service and repairs for our power measurement devices to our Chinese customers. His service laboratory is therefore an important and central service hub, allowing us to respond to customer concerns as promptly and reliably as possible, whether for retrofitting hardware options, device maintenance and cleaning, or troubleshooting and repair.

Not only at our headquarters in Oberursel do we set high standards for defining, documenting, and complying with certain quality and safety regulations, both normative and manufacturer-defined. To furthermore ensure the same quality standards and compliance with prescribed safety measures and tests in device servicing, we train our service partners in the same working methods. After all, our customers rely on consistent quality and reliability in our products. We are pleased to have cooperation partners like GMC-I China and, above all, Neil Xu, who share the same commitment to these important standards.

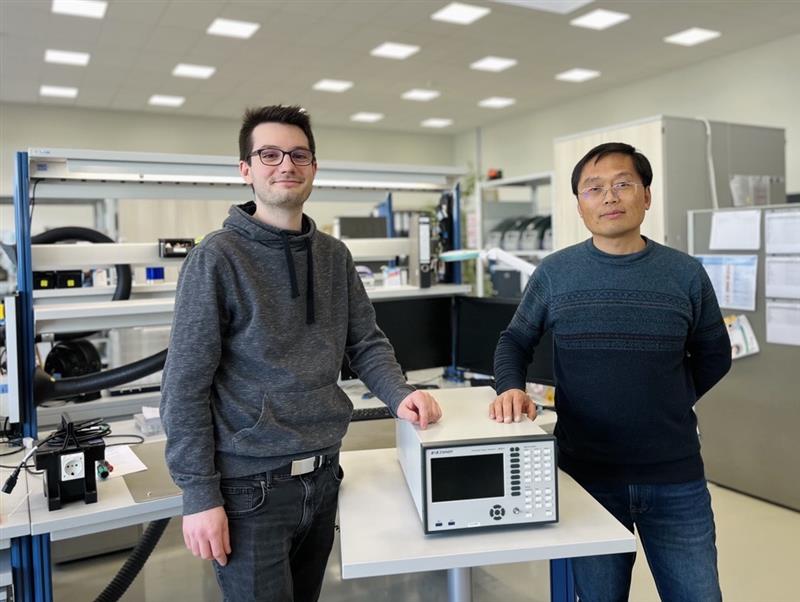

In this context, Neil Xu and our employee Arian Woldach, from our development department, invested two days in an intensive training session, which is conducted annually to comprehensively work through or refresh all key and necessary topics. With Arian, as being previously a service technician in our production department, during which he built deep experience and knowledge in device servicing of our power analyzers, Neil had the right teacher aside. The training particularly covered the following measures, procedures, and knowledge transfer:

- Required service laboratory equipment and its application

- ESD protection measures for handling relevant electronic components

- Device hardware structure and assembly compatibility

- Device maintenance and cleaning

- Replacement of hardware components with spare parts

- Installation and retrofitting of hardware modules and options

- Troubleshooting at module level

- Routine testing according to EN61010-1:2010, Annex F, including protective conductor testing

- Voltage withstand test

- Factory calibration with prior functional test

- Work processes and documentation for external service partners

Upon completion of the training in February this year, Neil Xu received his certificate and ongoing qualification, which continues to authorize him to perform the above-mentioned service tasks for our power measurement devices in China.

Packing intensive training and hands-on work into just a few days requires a great deal of focus and dedication, which Neil mastered with excellence. To allow him to unwind after the workday, engage in informal exchanges over dinner, and gain insights into the culture and sights of our neighboring metropolis, Frankfurt am Main, our Business Development team members Sahar Tahzibi and Patrick Fuchs naturally made this possible.

We sincerely thank Neil Xu for his commitment, his support for us on-site in China, and we look forward to continued great cooperation, as well as the next qualification training in Shanghai in the coming year.